Thermowood Cladding Suppliers

What is Thermowood ?

Its a beautiful, sustainable timber material produced by using chemical-free heat treatment.

Creating Thermowood

Created using Scandinavian softwood heated to 180 to 230 degrees Celsius in a kiln for up to 96 hours.

The use of steam helps to prevent wood splitting and become damaged during treatment.

Thermowood’s Characteristics & Qualities

This process causes chemical and structural changes to occur within the timber, which therefore alters some of its characteristics and qualities. Some of the characteristics and qualities that make Thermowood such a popular specie include

- Dimensionally Stable – The intensive heat the wood is exposed to during its production dries out deep into the core, causing all moisture and resin to be removed from the timber. Which means it doesn’t react to changes in humidity as drastically as untreated wood allowing it to retain its original shape .The wood also doesn’t secrete sap or resin even in high temperatures.

- Environmentally Friendly – The softwood used to produce Thermowood originates from well-managed, PEFC-certified forests, and as no chemicals or foreign substances are involved during its production. Produced by using solely natural methods.

- Resistance to Rot & Fungi – Due to the heating process breaking down hemicelluose, the wood doesn’t contain the appropriate nutrients to allow rot and fungi to grow and develop

- Increased Longevity – When wood is treated with heat, it’s average life span is prolonged and increased at a higher temperature.

- Improved Insulation – Wood that has been heat treated is much more porous than untreated wood, vastly improving its insulating properties

- Can be Recycled – Unlike pressure impregnated wood, Thermowood can be discarded or recycled as untreated wood when it is no longer required

Thermowood Uses

The thermal modifications of wood improves the wood properties, thereby expanding the range of applications in which the wood can be used.

External Uses

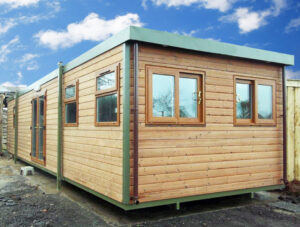

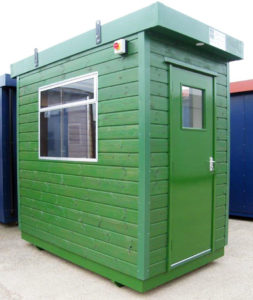

It’s high resistance to moisture and decay make it an excellent material for exterior projects. Some of its most popular external uses include

- External Cladding

- Decking

- Louvre Blades

- Brise Soleli

Interior Uses

It’s attractive appearance and removal of resin means that the timber is also ideal for interior projects such as:

- Interior Cladding

- Saunas

- Furniture

- Flooring

Thermowood Cladding Appearance

Temperature and the duration of exposure has an affect on the colour of the Thermowood. Different types of softwood densities can slightly change the colour. High temperature and long exposure produces a darker shade of Thermowood.

Thermowood Maintenance & Treatment

No surface treatment is required for Thermowood because of it’s long life. Options to add finish, stain or paint to the cladding to enrich its colour, left untreated it will naturally change to a silver grey similar to cedar and larch woods.